Top 5 Centrifugal Pump Working Principle

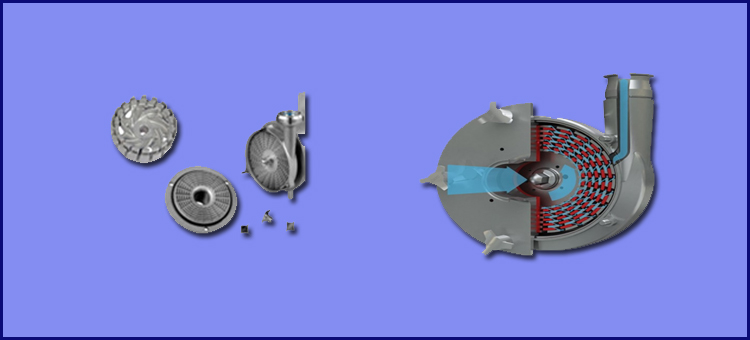

PMR INDIA, a based-renowned Centrifugal Pump Manufacturer, Supplier, Exporter, and Trader in Pune known for high-performance pumping solutions in specific applications, across industries. Our products include Pneumatic Centrifugal Pumps and Flow Centrifugal Pumps, which can effectively propel fluids of any dimension with efficiency and precision for larger applications. Check this for the working principle of Centrifugal Pumps and how they ensure a reliable, high-capacity transfer of fluids:

- Conversion of Kinetic Energy: Motor energy is consumed mechanically, and this is transformed into kinetic energy when the impeller is rotated.

- Fluid Acceleration: It creates a high velocity at which the fluid moves towards the discharge after it has been accelerated by the impeller.

- Centrifugal Force: It is a force that acts on a body moving in a circular path, which pushes the liquid outwards from the impeller center due to centrifugal force, and consequently, pressure generation.

- Flow Continuity: Liquid moves in this continuous space allowed to travel through the pump casing; this opened system ensures uninterrupted liquid transfer through it.

- Pressure Build-Up: Pressure is generated for the transmission of fluid within a pump when the liquid exits the impeller.

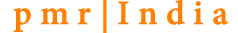

Types of Centrifugal Pumps

The centrifugal pump manufacturers in Pune, wherein quality pure comes with versatility because centrifugal pumps of all categories are manufactured as follows:

- Radial Flow Centrifugal Pump: Saves pressure at very high flow rates while the impeller pushes the fluid.

- Axial Flow Centrifugal Pump: Moves fluid axially and is designed for high-flow, low-pressure usages, such as a drainage system.

- Single-Stage Centrifugal Pump: Application where specific pump with an impeller and low flow high-pressure head.

- Multi-Stage Centrifugal Pump: One used in many impellers within the casing, and for applications where high pressures are required, it should be beneficial for transporting a fluid over long distances.

- End Suction Centrifugal Pump: A pumped suction at the end and is placed on the simplest design. It is commonly used for water and chemical transfer among its various applications.

Specifications of Centrifugal Pump

We have added below a technical sheet of our Centrifugal Pump that provides more technical information such as:

| Model | Flow Rate (Q) | Head (H) | Power (P) | Speed (N) | Efficiency (η) | Material | Temperature | Motor Protection |

|---|---|---|---|---|---|---|---|---|

| Industrial Horizontal | 500-2000 m³/h | 50-150 m | 30-150 kW | 2900-3600 rpm | 80-90% | Cast Iron/SS | -20 to 120°C | IP55 |

| Single Stage | 100-500 m³/h | 20-100 m | 10-50 kW | 2900-3600 rpm | 75-85% | Cast Iron/Bronze | -20 to 120°C | IP44, IP55 |

| Automatic Caustic Chemical | 50-200 m³/h | 30-70 m | 5-20 kW | 2900 rpm | 70-80% | Stainless Steel | -20 to 100°C | IP55 |

| Three Phase Monoblock | 200-1000 m³/h | 40-120 m | 15-75 kW | 2900-3600 rpm | 85-90% | - | - | - |

Benefits of the Centrifugal Pump

Centrifugal Pump Manufacturer in Pune and is one excellent export supplier for such pumps. These centrifugal pumps are made using best-in-class technologies and offer numerous advantages:

- Multi-Purpose: It handles other kinds of fluids, from water to chemicals, in different kinds of industries.

- Smooth in Operation: Operates with low vibrations and noises, thus increasing stability and quietness of performance.

- Cheapest: Here, the initial cost is also little and the maintenance is much lower than other types of pumps.

- Great efficiency: Excellent transfer of fluid and requires the least energy which is very important for large volume transfers.

- Simple Construction: It is simplified and easy to maintain, thus lowering the operational complexity.

Applications of Centrifugal Pump

As Centrifugal Pump Exporters and Traders in Pune, our pumps are highly demanded for multiple types of applications and used for improving performance, such as:

- Heating and air conditioning systems

- Food and beverage processing

- Desalination plants

- The pulp and paper industry

- Mining operations

- Marine and ship pumping systems

- HVAC systems

- Water supply and distribution

- Sewage and wastewater treatment

- Industrial fluid transfer

- Chemical processing

- Oil and gas pumping

- Agricultural irrigation

- Fire fighting systems

- Cooling water circulation in power plants

PMR INDIA, one of the leading centrifugal pump manufacturers in Pune, produces high-performance pumps designed to meet the rigorous demands of various industries. Utilizing advanced technology and sturdy construction, these pumps deliver exceptional performance and long service life.

With a focus on energy efficiency and cost-effectiveness, Our solutions are perfectly suited for industrial applications. Renowned for quality and reliability, PMR India centrifugal pumps maintain world-class standards, ensuring they meet the diverse needs of the industrial sector.